Solving What’s New Since You Installed That Wastewater System

Distributors are being asked to deliver reliability in a world where the waste stream has changed dramatically. Today, wastewater systems are being asked to work through solids like bed sheets, towels, blue jeans, etc., These things were never meant to be flushed. Many pumps in the field today were designed long before those changes arrived.

You’re working hard to solve a problem that cannot be solved with yesterday’s equipment. The solution isn’t another service call. It’s innovation. And more power!

The Problem Has Changed, Dramatically

Your customers are experiencing:

Bigger, bulkier solids

From shop towels to mop heads, from blue jeans to tennis shoes — items that were never supposed to be flushed are now making their way to lift stations. Keen Pump’s field reports show that traditional grinders simply weren’t built to handle this kind of abuse.

Higher duty cycles

Growing communities and high-use facilities mean pumps run longer and harder, far beyond their original design assumptions.

Abrasive contamination

More grit and plastics accelerate wear, shorten pump life, and increase callouts.

Aging infrastructure

Stations built 10–30 years ago are now dealing with massively different solids and loads.

You take the service call. You manage the frustration.

But the real issue is the tech beneath the waterline, not your support.

Keen Pump built the Pulverizer to finally close that gap.

Why Traditional Grinder Pumps Fall Short

Most grinder pumps rely on tearing and cutting. That means:

- Long fibers wrap around rotating parts

- Textiles wedge and jam

- Cutting surfaces dull quickly

- “Shredded” solids reform and clog downstream

That’s why “fixing” a clog keeps becoming the next service call.

The problem is never eliminated — just relocated.

Traditional grinders have reached their limit.

Keen Pump’s Solution: The Pulverizer — Built for Today’s Waste Stream

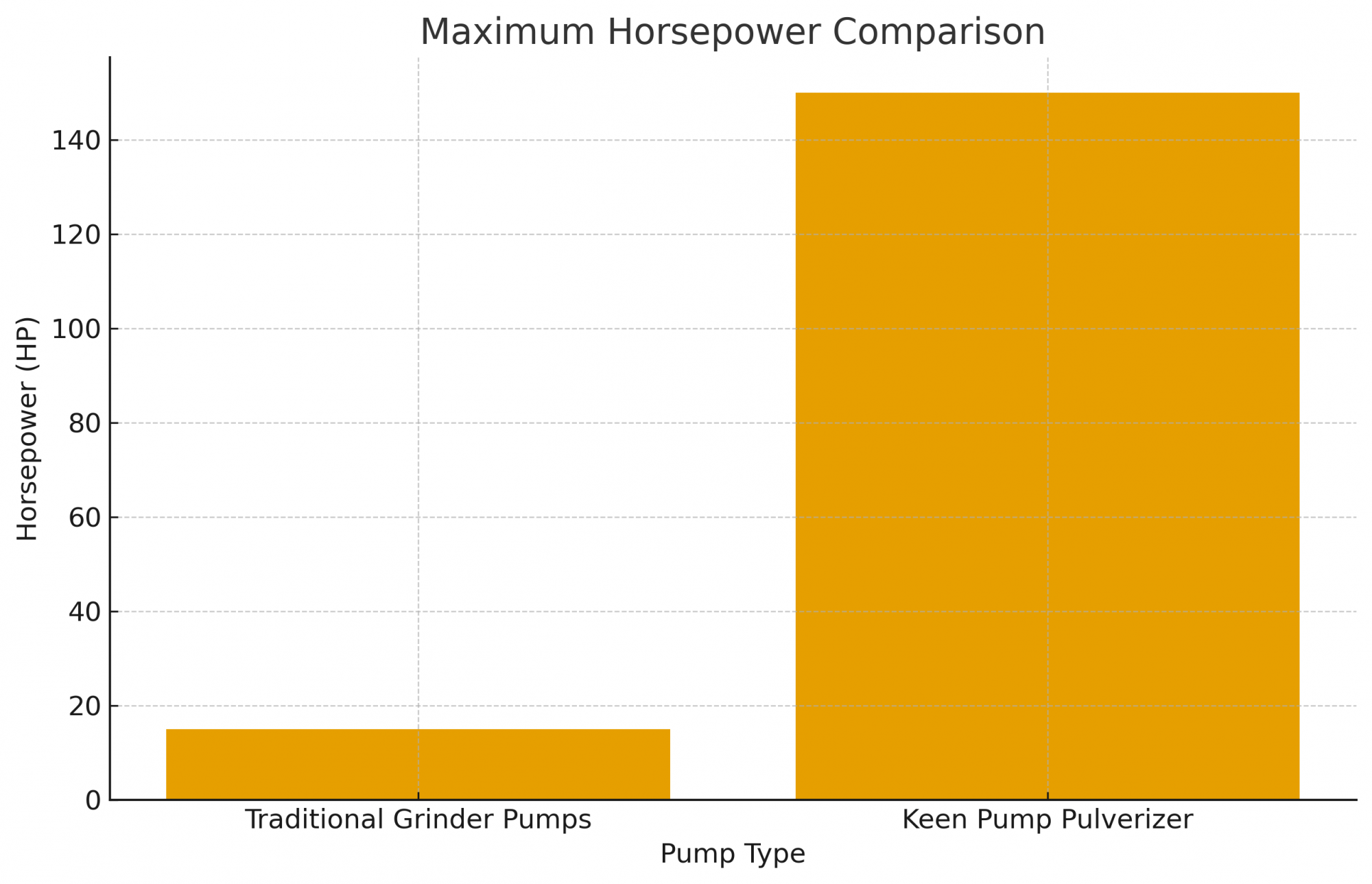

Traditional grinder pumps max out around 15 HP — which made sense when the toughest thing in the station was a hand towel. Today, waste streams include bulky textiles, commercial cleaning debris, plastics, and heavier foreign objects that require more torque and more cutting force.

The Keen Pump Pulverizer is a different class of pump, engineered to:

✅ Macerate solids into a fine slurry — not just tear them into clog-sized pieces

✅ Prevent solids from wrapping, jamming, or continuing downstream

✅ Maintain cutting performance longer across wear life

✅ Deliver the horsepower and torque needed for today’s loads

✅ Future-proof stations for a waste stream still evolving

This is how you prevent the clog from ever becoming a clog.

It’s built for the world that exists today and tomorrow.

Why This Matters for Distributors

Your name is attached to every solution you recommend.

We understand that completely, and we respect it.

Keen Pump designed the Pulverizer so that you can confidently say: “This pump is built for the world my customers operate in now.”

We’re not asking you to experiment.

We’re offering a proven upgrade to a proven problem.

You get:

- A reliable answer to repeat-headache stations

- Fewer unplanned callouts and emergency mobilizations

- Stronger product performance that protects your reputation

- Support from Keen Pump’s engineering and service teams whenever needed

The Keen Pump Retrofit Advantage

Keen Pump knows budgets and approvals don’t always allow for a new build.

So we engineered a smarter path:

-Keep the basin.Keep the rails. Keep the infrastructure. Upgrade the pump only. And the power you need to run it.

Through the Keen Pump RetroFit program, the Pulverizer can replace the existing pump, regardless of who originally manufactured the system.

Your customers don’t want a full overhaul. They want the clogging to stop. Now you can give them that.

You Don’t Have to Navigate This Alone

We know this is new.

We know upgrades raise questions.

And we know your reputation is on the line with every recommendation you make.

That’s exactly why Keen Pump is here. We’re not going to push a product,

but we are going to support you with solutions that match today’s challenges.

Let’s take a look at one of your problem stations together.

Ask every question. Challenge every assumption.

We’ll give you honest answers, real data, and clear guidance.

Let’s talk about the Pulverizer pump. You and your customers deserve it.